Chain Pulley Blocks: Quick Lift Brand

Specifications/Dimensions (mm)

| Capacity | MT | 1 | 2 | 3 | 5 | 10 |

| Number of falls of load chain | No. | 1 | 1 | 1 | 2 | 4 |

| Dimensions | ||||||

| A Hook suspension | mm | 400 | 461 | 575 | 805 | 950 |

| with trolley, ranges t&2 | mm | 430 | 500 | 705 | 690 | 950 |

| with trolley, range 3 | mm | 470 | 540 | 720 | - | - |

| B | mm | 180 | 180 | 230 | 280 | 480 |

| C | mm | 153 | 153 | 182 | 209 | 220 |

| H Hook admittance | mm | 32 | 32 | 42 | 51 | 75 |

| • Weight at 3 M | kg | 13 | 19 | 27 | 59 | 130 |

| • Extra weight per additional M lilt | kg | 1.8 | 2.6 | 3.0 | 5.7 | 10.1 |

| * Running pull on hand chain | kg | 30 | 33 | 36 | 41 | 43 |

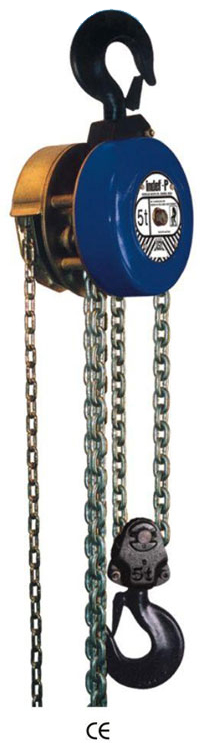

Triple spur gear chain pulley block - Model P

Manufactured in ISO 9001 : 2008 certified company

Manufactured in ISO 9001 : 2008 certified companyAssured quality & interchangeability of parts

Tested as per ISI procedure for 50% over load

Assured safety

Grade 80 load chain & zinc plated hand chain

Longer chain life

Rugged German design, in use for more than 30 years

Assured reliability

Double ball bearing supported load wheel

Smooth operation

Precision machine case hardened alloy steel gears

Long life, noseless operation

Fully pocketed S.G. iron cast load chain wheel

Long life, safe and smooth running

Anti corrosive powder coated zinc plated parts

Anti rust & better aesthetics

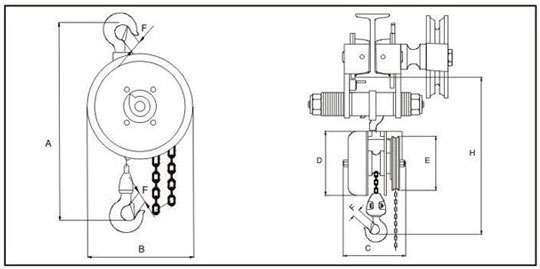

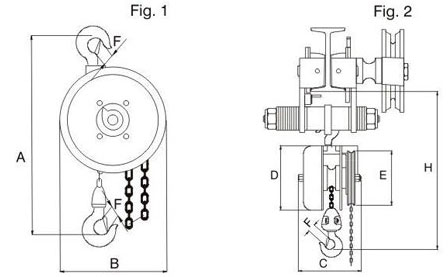

Specifications/Dimensions (mm)

| Capacity | MT | 0.5 | 1 | 2 | 3 | 5 | 7.5 | 10 |

| No. of falls | 1 | 1 | 2 | 2 | 2 | 3 | 4 | |

| Running pull on hand chain | Kgs. | 13 | 26 | 28 | 43 | 49 | 50 | 61 |

| Weight at 3 metre lift (approx.) | Kgs. | 21 | 21 | 30 | 35 | 60 | 88 | 126 |

| Extra weight per additional metre lift (approx.) | Kgs. | 2.9 | 2.9 | 4.3 | 4.3 | 5.2 | 7.0 | 14.4 |

| Capacity MT |

A | B | C | D | E | F | H | Mono blocks (not shown) H |

Thrust bearing in bottom block H |

| 0.5 T | 460 | 210 | 180 | 210 | 195 | 31 | 550 | 500 | 580 |

| 1T | 460 | 210 | 180 | 210 | 195 | 31 | 550 | 500 | 580 |

| 2 T | 560 | 240 | 180 | 210 | 195 | 37 | 665 | 620 | 760 |

| 3 1 | 625 | 240 | 200 | 210 | 195 | 42 | 759 | 635 | 825 |

| 5 T | 810 | 320 | 225 | 275 | 270 | 51 | 885 | 780 | 1010 |

| 7.5 T | 910 | 455 | 225 | 275 | 270 | 75 | 1017 | 952 | 1135 |

| 10 T | 990 | 515 | 225 | 275 | 270 | 75 | 1120 | 1025 | 1240 |

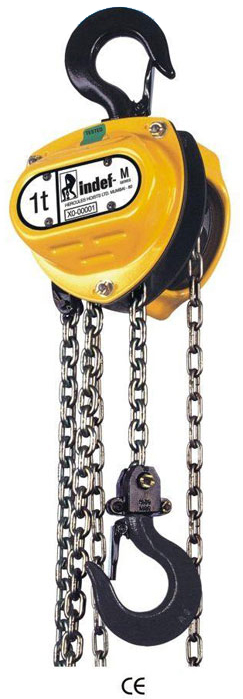

Triple spur gear chain pulley block - Model M

Light weight & sturdy

Light weight & sturdy

Ease of handling

Lifelong lubrication

Minimal maintenance required

Surface hardened gears

Extended working life

Use of needle roller bearings

High operating efficiency

Smooth passage of load chain

Machined guide rollers

Smooth hand chain operation

Unique cover design

Self sustaining maintenance free friction brake

Reduced downtime

Grade 80 load chain for strength & wear resistance

Longer chain life

Anti corrosive powder coated finish

Better aesthetics

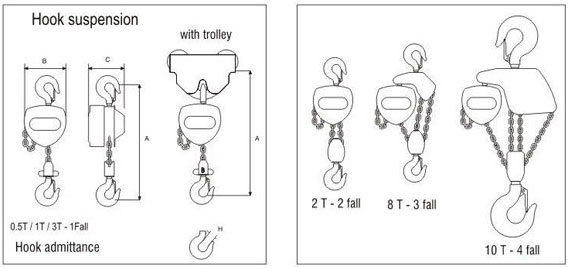

Specifications/Dimensions (mm)

| Capacity | MT | 0.5 | 1 | 2 | 2.5 | 3 | 5 | 8 | 10 |

| Number of falls of load chain | No. | 1 | 1 | 2 | 1 | 1 | 2 | 3 | 4 |

| Dimensions | |||||||||

| A Hook suspension | mm | 335 | 400 | 461 | 530 | 575 | 805 | 880 | 950 |

| with trolley, ranges 1&2 | mm | 365 | 430 | 500 | 560 | 705 | 690 | 930 | 950 |

| with trolley, range 3 | mm | 405 | 470 | 540 | 605 | 720 | - | - | - |

| B | mm | 155 | 180 | 180 | 238 | 230 | 280 | 430 | 480 |

| C | mm | 144 | 153 | 153 | 209 | 182 | 209 | 220 | 220 |

| H Hook admittance | mm | 27 | 32 | 32 | 42 | 42 | 51 | 75 | 75 |

| • Weight at 3 M | kg | 10 | 13 | 19 | 29 | 27 | 59 | 94 | 130 |

| • Extra weight per additional M lift | kg | 1.4 | 1.8 | 2.6 | 3.0 | 3.0 | 5.7 | 7.9 | 10.1 |

| • Running pull on hand chain | kg | 28 | 30 | 33 | 37 | 36 | 41 | 46 | 43 |

Triple spur gear chain pulley block - Model M

Light weight & sturdy

Light weight & sturdy

Ease of handling

Lifelong lubrication

Minimal maintenance required

Surface hardened gears

Extended working life

Use of needle roller bearings

High operating efficiency

Smooth passage of load chain

Machined guide rollers

Smooth hand chain operation

Unique cover design

Self sustaining maintenance free friction brake

Reduced downtime

Grade 80 load chain for strength & wear resistance

Longer chain life

Anti-corrosive powder coated finish

Better aesthetics

Compact design

Low headroom & light weight

Specifications/Dimensions (mm)

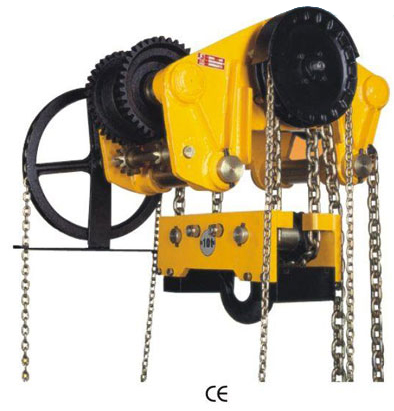

| Capacity MT |

No. ot falls | For each hand chain* 'Hand chain required to be passed over for lifting load through one metre... metres (approx.) |

Running pull on hand chain |

Hook opening | Weight for 1M addl. lift (approx.) |

| 161 | 6 | 468 | 45 Kg. | 95 mm | 14.5 Kg. |

| 20T | 8 | 624 | 46X2 Kg. | 95 mm | 20.2 Kg. |

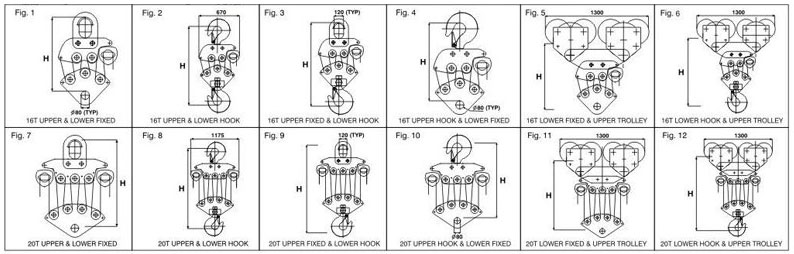

| Fig. | 16 Tonne | 20 Tonne | ||||||||

| Combinations | 16T | 20T | Length mm |

Width mm |

Headroom 'H' mm |

Weight for 3M lilt (kg.) (approx.) |

Length mm |

Width mm |

Headroom H' mm |

Weight tor 3 M Hit (kg.) (approx.) |

| Upper fixed eye suspension and lower fixed | 1 | 7 | 670 | 220 | 640 | 138 | 1175 | 220 | 640 | 200 |

| Upper & lower swiveling hook | 2 | 8 | 670 | 220 | 1175 | 218 | 1175 | 220 | 1175 | 280 |

| Upper fixed eye suspension and lower swiveling hook | 3 | 9 | 670 | 220 | 985 | 178 | 1175 | 220 | 985 | 240 |

| Upper swiveling hook and lower fixed | 4 | 10 | 670 | 220 | 700 | 178 | 1175 | 220 | 700 | 240 |

| Trolley suspension and lower fixed | 5 | 11 | 1300 | -F+360 | 795 | 440 | 1300 | -F+360 | 795 | 500 |

| Trolley suspension and lower swiveling hook | 6 | 12 | 1300 | -F+360 | 1140 | 470 | 1300 | •F+360 | 1140 | 540 |

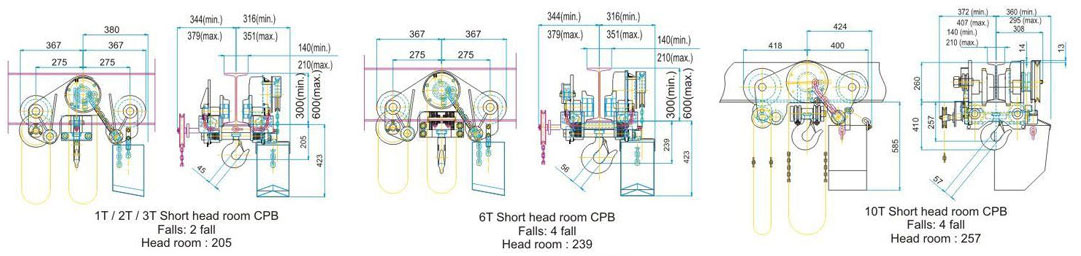

Triple spur gear chain pulley block - Model-USH (Ultra short headroom)

Compact design

Compact design

Low headroom applications

Integral trolley

Ultra short headroom design for maximum clear lift

Grade 80 load chain & zinc plated hand chain

Longer chain life

Double ball bearing supported load wheel

Smooth operation

Precision machine case hardened alloy steel gears

Long life, noiseless operation

Fully pocketed S.G. iron cast load chain wheel

Long life, safe and smooth running

Anti corrosive powder coated zinc plated parts

Anti rust & better aesthetics

Specifications/Dimensions (mm)

| Capacity | MT | 1T/2T | 3T | 6T | 10T |

| No. of fails | 2 | 2 | 4 | 4 | |

| Chain dia | mm | 8 | 8 | 8 | 12 |

| Headroom | mm | 205 | 205 | 239 | 350 |

| Weight at 3M Lift | kg | 110 | 125 | 210 | 350 |

| Weight per additional 1 meter lift | kg | 4.3 | 4.3 | 7 | 14.4 |

| Min. I-beam height | 300 | 300 | 300 | 300 |

Triple spur gear chain pulley block - Model-SP (Spark proof)

Tested as per ISI procedure for 50% over load

Tested as per ISI procedure for 50% over load

Assured safety

Grade 80 load chain & zinc plated hand chain

Longer chain life

Rugged German design, in use for more than 30 years

Assured reliability

Double ball bearing supported load wheel

Smooth operation

Precision machine case hardened alloy steel gears

Long life, noiseless operation

Non-ferrous parts like chain wheels, chain guides, ratchet wheel and stripping fork

Eliminates spark generation possibilities during rubbing of mating components

Anti-corrosive powder coated zinc plated parts

Anti rust & better aesthetics

Specifications/Dimensions (mm)

| Capacity | MT | 0.5 | 1 | 2 | 3 | 5 | 7.5 | 10 |

| No. of falls | 1 | 1 | 2 | 2 | 2 | 3 | 4 | |

| Running pull on hand chain | Kgs. | 13 | 26 | 28 | 43 | 49 | 50 | 61 |

| Weight at 3 metre lift (approx) | Kgs. | 21 | 21 | 30 | 35 | 60 | 88 | 126 |

| Extra weight per additional metre lift (approx.) | Kgs. | 2.9 | 2.9 | 4.3 | 4.3 | 5.2 | 7.0 | 14.4 |

| Capacity MT |

A | B | C | D | E | F | H | Mono blocks (not shown) H |

Thrust bearing in bottom black H |

| 0.5 T | 460 | 210 | 180 | 21C | 195 | 31 | 550 | 5G0 | 580 |

| 1 T | 460 | 210 | 180 | 210 | 195 | 31 | 550 | 500 | 580 |

| 2 T | 560 | 240 | 180 | 210 | 195 | 37 | 665 | 620 | 760 |

| 3T | 625 | 240 | 200 | 210 | 195 | 42 | 759 | 635 | 825 |

| 5T | 810 | 320 | 225 | ?75 | 270 | 51 | 885 | 780 | 1010 |

| 7.5 T | 910 | 455 | 225 | 275 | 270 | 75 | 1017 | 952 | 1135 |

| 10 T | 990 | 515 | 225 | 275 | 270 | 75 | 1120 | 1025 | 1240 |

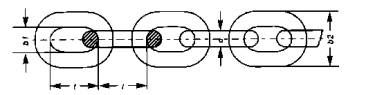

A.S.G 80 CHAIN

Alloy Steel Chain Grade 80 (Class 8) DIN5687, DIN5688, ISO3076 Grade T (8)

Safety with Grade 80

To achieve the consistent high level of quality and reliability of our products.

· Electronically controlled chain machines have been specially built and developed to provide advanced manufacturing processing.

· Electronically controlled chain machines have been specially built and developed to provide advanced manufacturing processing.

· High grade alloy steel are carefully chosen.

· Strict control of material acceptance and processing is carried out by skilled personnel.

· Sophisticated multi-process heat-treatment techniques have been developed.

· Non-destructive testing systems are used with magnetic crack detection (magna flux system),being applied during final inspection.

· All accessories, such as hooks, connectors etc.,are produced by special hot forging techniques carried out on modern forging hammers.

· Close dimensional controls are carried our at all stages of manufacture.

To ensure the chains have a high capacity to absorb shock loadings, they are produced so that they will give a minimum extension of 20% under a destruction test before fracture occurs.  They are also subjected to sample bend testing.

Elongation at break : self coloured,min 20% ;bright finished, min 15%

Elongation at break : self coloured,min 20% ;bright finished, min 15%

Factor working load limit :breaking load=1:2,5:4(200:500:800N/mm2 );

Deflection min.f=0.8 × d

These sling chains are only available in welded finish.

DIMENSION AND PROPERTIES

| Serial No. |

Width | Weight | Approx Load limit | Test Load | Breaking load min. |

||

| Normal size | Inside | outside | ||||||

| mm | a min. |

b max. |

Kg m |

t | KN | KN | |

| 1. | 6 x 18 | 7.5 | 21 | 0.79 | 1.1 | 27 | 45.2 |

| 2. | 7 x 21 | 9 | 24.5 | 1.07 | 1.5 | 37 | 61.6 |

| 3. | 8 x24 | 10 | 28 | 1.38 | 2 | 48 | 80.4 |

| 4. | 10 x 30 | 12.5 | 35 | 2.2 | 3.2 | 76 | 125 |

| 5. | 11 x 43 | 12.6 | 36.5 | 2.33 | 3.8 | 92 | 154 |

| 6. | 12 x 36 | 15 | 42 | 3.1 | 4.6 | 109 | 181 |

| 7. | 13 x 39 | 16.3 | 46 | 3.8 | 5 | 128 | 214 |

| 8. | 14 x 42 | 18 | 49 | 4.13 | 6.3 | 150 | 250 |

| 9. | 16 x 48 | 20 | 56 | 5.63 | 8 | 192 | 320 |

| 10. | 18 x 54 | 23 | 63 | 6.85 | 10 | 246 | 410 |

| 11. | 19 x 57 | 23.7 | 63.2 | 7.7 | 11.3 | 270 | 450 |

| 12. | 20 x 60 | 25 | 70 | 8.6 | 12.5 | 300 | 500 |

| 13. | 22 x 66 | 28 | 77 | 10.2 | 15.3 | 366 | 610 |

| 14. | 24 x 72 | 32 | 82 | 12.78 | 18 | 432 | 720 |

| 15. | 26 x 78 | 35 | 91 | 14.87 | 21.3 | 510 | 850 |

| 16. | 30 x 90 | 38 | 105 | 19.6 | 28.3 | 678 | 1130 |

| 17. | 32 x 96 | 40 | 106 | 22.29 | 678 | 772 | 1286 |

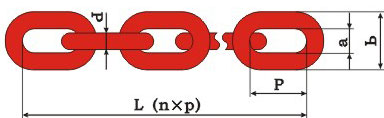

M.S. CHAIN

The dimensions and properties completely confirm to Grade B and C requirements specified in the National Industrial Standards GB/ T 12718 and DIN22252- 1

The dimensions and properties completely confirm to Grade B and C requirements specified in the National Industrial Standards GB/ T 12718 and DIN22252- 1 /2

/2

Material : High alloy steel

Breaking Elongation : 12% max

Finish : Rust preventive oil coating or black painting

DIMENSION AND PROPERTIES

| Serial No. | Width | Weight | Breaking Load min. | ||

| Normal size | Inside | outside | ||||

| dxp mm |

a min. |

b max. |

Kgs max |

KN min |

|

| 1. | 10 x 40 | 15 | 37 | 1.9 | 125 |

| 2. | 13 x 52 | 19.5 | 48.5 | 3.31 | 214 |

| 3. | 14 x50 | 18.5 | 49.5 | 4 | 250 |

| 4. | 16 x 64 | 24 | 59 | 4.97 | 320 |

| 5. | 19 x 76 | 28.5 | 69.5 | 6.92 | 450 |

| 6. | 22 x 86 | 27 | 74 | 9.5 | 610 |

| 7. | 26 x 92 | 31 | 86 | 13.7 | 850 |

LASHING CHAIN

Material : high quality alloy-steel

Material : high quality alloy-steel

Surface Treatment : self colour, polishing, blackened, painted, plastic coating, hot-dip galvanized, electro-galvanized, etc.

Manufacture Standard : ISO, EN, DIN, BS, JIS, ASTM,

Quality Grade : G70, G80, G100

Safety Factor : 4min.

DIMENSION AND PROPERTIES

| Serial No. | Width | Weight | Breaking Load min. | ||

| Normal size | Inside | outside | ||||

| dxp mm |

a min. |

b max. |

Kgs max |

KN min |

|

| 1. | 13 x 82 | 23.4 | 54.6 | 2.95 | 214 |

| 2. | 16 x 100 | 28.8 | 67.2 | 4.45 | 320 |